1️⃣ Boosted Production Speed

- Robots can assemble, weld, paint, and pack products much faster than humans.

- They run 24/7 without breaks, ensuring factories meet high demand.

- Perfect for industries under pressure for mass production (automotive, electronics, consumer goods).

2️⃣ Higher Accuracy & Consistency

- Robots maintain precision in every task, reducing errors in assembly and finishing.

- Ensures consistent quality standards, which builds customer trust.

- Minimizes waste due to defective products.

3️⃣ Cost Efficiency

- Reduces labor costs for repetitive, low-skill tasks.

- Fewer errors mean lower rework and return rates.

- Long-term savings by increasing productivity per square foot.

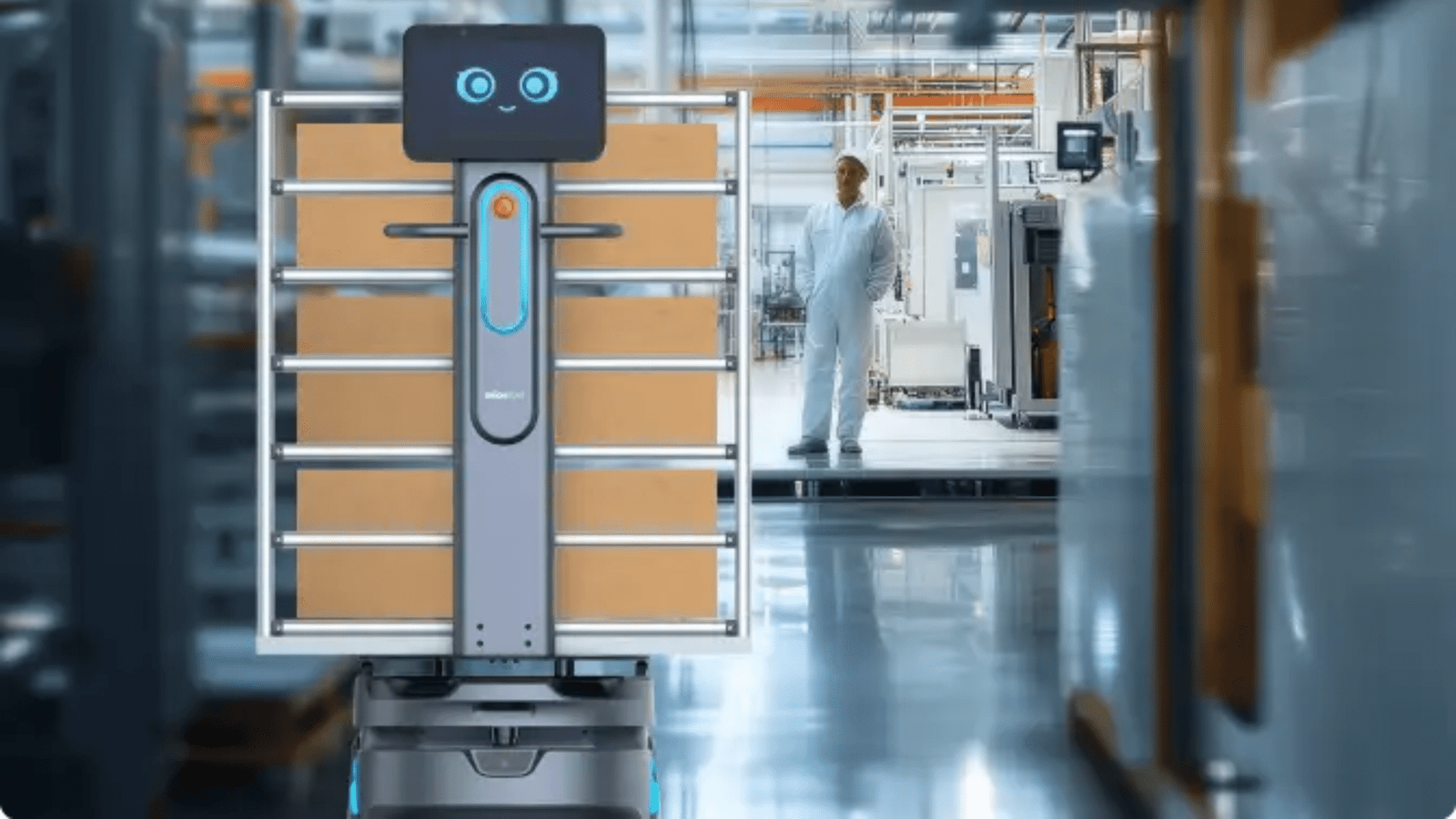

4️⃣ Worker Safety & Ergonomics

- Robots handle dangerous, repetitive, or physically heavy tasks, protecting workers.

- Reduces workplace injuries, fatigue, and accidents.

- Allows humans to focus on supervision, innovation, and problem-solving.

5️⃣ Scalability & Flexibility

- Robots can be reprogrammed for different tasks (assembly lines, packaging, testing).

- Helps factories adapt to new product launches or design changes quickly.

- Ideal for industries with fluctuating demand.

6️⃣ Integration with AI & Smart Manufacturing

- Robots combined with AI, IoT, and sensors provide real-time monitoring.

- Factories get data-driven insights for predictive maintenance, inventory control, and energy efficiency.

- Forms the backbone of Industry 4.0 and smart factories.

7️⃣ Global Competitiveness

- Leading manufacturers worldwide use robots to stay ahead.

- Factories that adopt robots remain competitive in cost, speed, and quality.

- Strengthens their position in global supply chains.